The True Economics of Machine Control: Why Your Technology Partner Choice Matters

Understanding total cost of ownership and operational benefits in modern earthmoving

Machine control technology has evolved from a luxury add-on to an essential component of competitive earthmoving operations. Yet many operators still approach these systems with outdated assumptions about cost, complexity, and control. Your technology partner choice determines your long-term success.

Beyond Purchase Price: Real Total Cost of Ownership

The conversation around machine control often focuses solely on upfront costs, missing the broader economic picture that determines long-term profitability.

Traditional Approach Hidden Costs:

- Installation and commissioning fees

- Minimal operator training

- Ongoing technical support charges

- Proprietary repair requirements

- Software licensing and updates

- Excessive downtime during service calls

Modern Integrated Approach Benefits:

- Transparent system pricing with flexible installation options

- Comprehensive training programmes building internal expertise

- In-house repair capabilities and full system ownership

- Remote support capabilities with predictable operating costs

Technology That Delivers Real-World Results

Precision That Pays

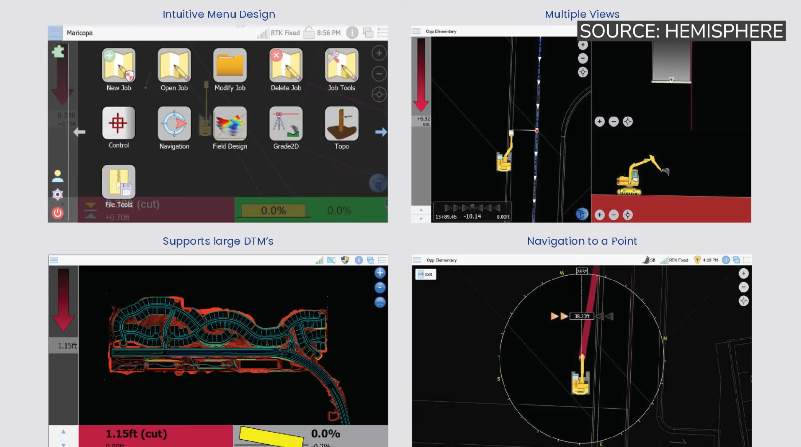

Stonex STX-Dig & Hemisphere Systems deliver centimetre-level accuracy with direct bottom-line benefits:

- Reduced over-excavation saves material handling costs

- First-pass accuracy eliminates costly rework

- Consistent grade achievement speeds project completion

- Operator confidence increases productivity across all skill levels

Both systems include 3-year comprehensive warranty protection and are built specifically for Australian operating conditions.

The Training Advantage: Building Internal Capability

The most significant long-term benefit comes from developing internal expertise rather than remaining dependent on external technicians.

Complete Training Ecosystem

Installation Mastery Programmes:

- Stonex STX-Dig Installation Masterclass: Self-paced learning with comprehensive certification

- Hemisphere VR1000 Installation Masterclass: Modular course structure with advanced calibration techniques

- Operator training so they can get the best out of their machines

- Professional certification recognised across the industry

Online Training for All Levels of the business so everyone is on the same page.

Flexible Implementation Options

Different operations have different capabilities. Modern solutions accommodate this reality:

Full Professional Installation: Complete turnkey service with on-site calibration and immediate operational readiness.

Calibration-Only Service: Cost-effective option for capable internal teams with professional verification and same warranty protection.

Supported Self-Installation: Maximum cost savings with complete remote support and professional backup when needed.

Support That Actually Supports Operations

Comprehensive Remote Capabilities

Local Expertise and Rapid Response

Investment Protection and Long-Term Value

Technology Built for Australian Conditions

The Economics That Matter

A typical operation with 3 excavators experiences:

- $45,000 savings on initial system purchase vs. major competitors

- $15,000 annual savings on installation and service costs

- $8,000 annual savings on parts and repairs

- $12,000 savings in reduced downtime through faster service

Total 3-year savings: $125,000+

Investment Protection Through Internal Expertise

The most valuable protection for any technology investment is internal capability:

- Reduced dependence on external technicians

- Lower ongoing costs through internal expertise

- Faster problem resolution with trained personnel

- Better system utilisation through deeper understanding

Making the Right Partnership Decision

Successful machine control implementations result from partnerships that provide:

✓ Technology that performs reliably in real-world Australian conditions ✓ Training that builds genuine internal capability at all organisational levels ✓ Support that responds with 2-hour emergency response times ✓ Flexibility that adapts with multiple installation and service options ✓ Economics that make sense with transparent pricing and 3-year warranty ✓ Partnership that grows with comprehensive remote support capabilities

The Path Forward

Modern machine control technology offers unprecedented opportunities to improve operational efficiency, reduce costs, and enhance competitive positioning. Success lies not just in choosing the right technology, but in partnering with providers who understand that your success determines their success.

When evaluating machine control solutions, consider the complete picture: technology performance, training quality, support responsiveness, implementation flexibility, and long-term partnership potential.

Your next earthmoving project deserves the advantage that comes from making the right technology partnership decision.

For more information about machine control solutions and training programmes, contact Red Edge Resources at 1300 769 359 or visit www.rededgeresources.com.au