Prevent Collisions. Protect Lives. Enhance Productivity.

Red Edge Resources is proud to deliver the Orlaco Collision Avoidance System (CAS) – the most advanced collision prevention technology for mining, construction, and earthmoving operations across Australia. Orlaco’s intelligent CAS technology combines radar detection, camera systems, and real-time alerts to eliminate accidents, protect ground personnel, and create safer worksites.

What is the Orlaco Collision Avoidance System (CAS)?

The Orlaco CAS is an integrated safety system that uses advanced sensor technology, cameras, and intelligent software to detect people, vehicles, and obstacles around heavy machinery. The system provides real-time visual and audible warnings to operators, preventing collisions before they happen.

How Orlaco CAS Works:

- Detection – Multiple radar sensors and cameras continuously monitor zones around the machine

- Analysis – Intelligent software identifies people, vehicles, and obstacles in real-time

- Alert – Operators receive instant visual and audible warnings on in-cab displays

- Prevention – Optional machine lockout stops equipment movement when danger is detected

Why Choose Orlaco Collision Avoidance System?

The Most Dangerous Worksite Hazards:

- Reversing accidents – Limited rear visibility causes fatalities

- Blind spot collisions – Operators can’t see ground personnel

- Vehicle-to-vehicle impacts – Multiple machines working in close proximity

- Pedestrian strikes – Workers moving around active equipment

- Low visibility conditions – Dust, darkness, and weather reduce visibility

Orlaco CAS eliminates these risks with proven collision prevention technology.

Key Benefits:

✓ Save Lives – Protect ground personnel from heavy machinery accidents

✓ Prevent Costly Accidents – Eliminate equipment damage and downtime

✓ Improve Compliance – Meet Australian safety standards and regulations

✓ Reduce Insurance Costs – Demonstrate proactive safety measures

✓ Boost Operator Confidence – Work safely in confined spaces and low visibility

✓ Increase Productivity – Operators work faster with complete awareness

✓ Australian Support – Full installation and technical support from Red Edge Resources

Orlaco CAS Features & Technology

1. Multi-Sensor Detection Technology

Comprehensive coverage using multiple detection methods:

Radar Sensors

- 360° detection coverage around the machine

- Detects people, vehicles, and obstacles in all weather conditions

- Works in dust, fog, rain, and darkness

- Range: 1-50 metres (configurable)

- Immune to environmental interference

Camera Integration

- High-definition cameras provide visual confirmation

- Automatic display switching when objects detected

- Night vision capability with infrared illumination

- Records incidents for documentation and training

Ultrasonic Sensors (Optional)

- Close-range detection for precise manoeuvring

- Ideal for reversing and confined space operations

- Detects objects as close as 0.3 metres

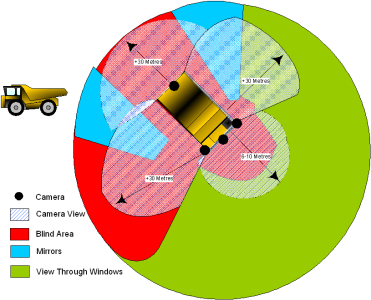

2. Configurable Detection Zones

Customise safety zones for your specific operation:

- Warning Zones – Visual and audible alerts when objects enter outer zones

- Danger Zones – Increased alert intensity in critical areas

- Lockout Zones – Automatic machine shutdown when objects enter high-risk areas

- Blind Spot Coverage – Targeted detection in operator blind spots

- Directional Zones – Different zones for forward, reverse, and side movement

Zone Configuration Options:

- Adjustable detection distances (1-50m)

- Multiple zone shapes and sizes

- Speed-dependent zone expansion

- Machine function-specific zones (e.g., slewing, reversing)

3. Intelligent Alert System

Multi-level warnings ensure operators respond appropriately:

Visual Alerts

- In-cab display shows detected objects in real-time

- Colour-coded warnings: Green (clear), Yellow (caution), Red (danger)

- Distance indicators show how close objects are

- Directional arrows indicate where the hazard is located

- Integration with existing machine control displays

Audible Alerts

- Progressive warning tones increase with danger level

- Voice messages provide clear instructions

- Directional audio indicates hazard location

- Adjustable volume for noisy environments

External Alerts

- Flashing beacons warn ground personnel

- External sirens alert nearby workers

- Reversing alarms integrated with CAS system

4. Data Logging & Fleet Management

Comprehensive incident tracking and reporting:

- Event recording – All detections and warnings logged with timestamp

- Video recording – Automatic recording when objects detected

- GPS location data – Know exactly where incidents occurred

- Operator identification – Track which operator was involved

- Integration with Telematics Guru – Remote fleet monitoring

- Reporting tools – Generate safety reports for compliance

Target Keywords: collision avoidance data logging, safety incident tracking, fleet safety monitoring, compliance reporting system

Orlaco CAS Applications

Mining Equipment Collision Avoidance

Critical safety for mining operations:

- Haul trucks – Detect light vehicles and personnel around large trucks

- Excavators – Monitor blind spots during digging and slewing

- Wheel loaders – Prevent reversing accidents at stockpiles

- Dozers – Detect personnel in push zones

- Drill rigs – Monitor movement zones during relocation

- Graders – Protect workers during road maintenance

Target Keywords: mining collision avoidance system, haul truck safety system, excavator collision prevention, loader proximity detection, mining equipment CAS Australia

Construction Site Safety Systems

Protect workers on busy construction sites:

- Excavators & backhoes – Prevent strikes during trenching and excavation

- Mobile cranes – Monitor swing radius and load zones

- Concrete trucks – Detect personnel during reversing

- Compactors & rollers – Protect workers on road projects

- Telehandlers – Prevent collisions in confined spaces

Earthmoving & Civil Works

Enhanced safety for earthmoving operations:

- Scrapers – Monitor large equipment in high-traffic areas

- Articulated dump trucks – Prevent reversing accidents

- Graders – Protect survey crews and ground personnel

- Water carts – Detect vehicles and workers on haul roads

Target Keywords: earthmoving safety system, civil construction collision avoidance, scraper proximity detection, ADT safety system

Ports, Logistics & Warehousing

Prevent collisions in high-traffic environments:

- Container handlers – Detect personnel in container yards

- Reach stackers – Monitor blind spots during stacking

- Heavy forklifts – Prevent collisions in warehouses

- Mobile harbour cranes – Protect workers in port operations

Orlaco CAS System Components

Detection Hardware

- Radar sensors (2-8 units depending on machine size)

- HD cameras with night vision (4-8 units)

- Ultrasonic sensors (optional, for close-range detection)

- Mounting brackets and protective housings

- Red Edge braided cables for durable connections

In-Cab Display & Control

- 7″ to 10″ touchscreen displays

- High-brightness for Australian sunlight (up to 1000 nits)

- Intuitive interface with real-time detection visualisation

- Integration with existing machine control displays

- Webbair IMC integration capability

Alert Systems

- Visual warning lights (in-cab and external)

- Audible alarms and voice messages

- Vibration alerts (optional seat/steering wheel)

- External beacons for ground personnel warning

Recording & Monitoring

- DVR system with SD card or HDD storage

- GPS module for location tracking

- 4G connectivity for remote monitoring (optional)

- Integration with Telematics Guru fleet management

Orlaco CAS vs. Traditional Safety Measures

| Traditional Methods | Orlaco CAS |

|---|---|

| Spotters required for reversing | Automatic detection, no spotter needed |

| Limited visibility in dust/darkness | Works in all weather and light conditions |

| Operator relies on mirrors | 360° sensor coverage with alerts |

| Reactive – accidents still occur | Proactive – prevents accidents before they happen |

| No incident documentation | Complete video and data logging |

| High ongoing labour costs | One-time investment, minimal maintenance |

Australian Standards & Compliance

Orlaco CAS helps meet Australian workplace safety requirements:

✓ Work Health and Safety Act 2011 – Duty of care to provide safe workplace

✓ AS 2294.1 – Earth-moving machinery safety standards

✓ Mining Safety Regulations – State-specific mining safety requirements

✓ ISO 5006 – Earth-moving machinery operator visibility standards

✓ Construction Industry Standards – Site-specific safety requirements

Demonstrate compliance and reduce liability with proven safety technology.

Red Edge Installation & Support Services

Professional CAS Installation Australia-Wide

Red Edge’s certified technicians provide complete collision avoidance system installation:

Site Assessment

- Machine inspection and measurement

- Optimal sensor placement design

- Detection zone configuration planning

- Integration with existing systems review

Installation Services

- On-site installation at your yard or job site

- Professional sensor mounting and alignment

- Red Edge braided cable installation for durability

- Display and control system integration

- Webbair IMC integration (if required)

- Telematics Guru connectivity setup

Calibration & Testing

- Sensor calibration and verification

- Detection zone configuration and testing

- Alert system setup and adjustment

- Machine lockout testing (if applicable)

- Operator familiarisation and training

Documentation & Handover

- System configuration documentation

- Operator training manuals

- Maintenance schedules

- Compliance certificates

- Warranty registration

Comprehensive Training Programmes

Ensure your team maximises CAS effectiveness:

- Operator Training – Understanding alerts and proper response

- Maintenance Training – Basic system checks and cleaning

- Supervisor Training – Data review and incident analysis

- Online Resources – Access to Red Edge Knowledge Portal

- Certification Programmes – Documented training completion

Ongoing Technical Support

- Rapid Response – 2-hour response time for technical support

- Phone Support – 1300 769 359

- Remote Diagnostics – Quick troubleshooting via internet connection

- Warranty Service – Full manufacturer warranty support

- Spare Parts – Available through Red Edge online parts store

- System Upgrades – Expand capabilities as technology advances

Why Choose Red Edge for Orlaco CAS?

50+ Years Combined Experience – Deep understanding of heavy machinery safety

Certified Installation Technicians – Factory-trained Orlaco specialists

Mobile Service Fleet – Fully-equipped vehicles for on-site installation across Australia

Integrated Safety Solutions – Combine CAS with Webbair IMC, cameras, and telematics

Australian Support Network – Local expertise, fast response, genuine parts

Proven Track Record – Trusted by major mining and construction companies

Comprehensive Training – Ensure your team uses the system effectively

Return on Investment – Orlaco CAS

Cost of Accidents Without CAS:

- Fatality – Unlimited liability, reputational damage, operations shutdown

- Serious Injury – $500,000+ in compensation and legal costs

- Equipment Damage – $50,000-$500,000 repair costs plus downtime

- Minor Incidents – $10,000-$50,000 in repairs and lost productivity

- Insurance Premiums – Increased costs after incidents

Benefits of Orlaco CAS Investment:

✓ Prevent even one serious accident – System pays for itself

✓ Reduce insurance premiums – Demonstrate proactive safety measures

✓ Eliminate spotter costs – Reduce ongoing labour expenses

✓ Increase productivity – Operators work confidently and efficiently

✓ Protect company reputation – Demonstrate commitment to safety

✓ Improve employee morale – Workers feel valued and protected

Typical ROI: 12-24 months through accident prevention and productivity gains

Orlaco CAS Technical Specifications

| Feature | Specification |

|---|---|

| Detection Technology | Radar, camera, ultrasonic (optional) |

| Detection Range | 1-50 metres (configurable) |

| Detection Angle | 360° coverage (with multiple sensors) |

| Display Size | 7″ to 10.1″ touchscreen |

| Display Brightness | Up to 1000 nits |

| Operating Temperature | -30°C to +70°C |

| Protection Rating | IP68 / IP69K |

| Power Supply | 12V / 24V DC |

| Alert Types | Visual, audible, voice, vibration |

| Recording | DVR with SD/HDD storage |

| Connectivity | Bluetooth, Wi-Fi, 4G (optional) |

| Integration | Machine control, hydraulics, telematics |

| Compliance | AS 2294.1 |