Take Back Control: How Red Edge Resources Revolutionises Machine Control Economics

Slash your machine control costs by up to 40% whilst gaining complete operational control

In today’s competitive construction and mining landscape, every dollar counts. Yet many operators find themselves trapped in expensive, inflexible machine control arrangements that drain budgets and limit operational freedom. At Red Edge Resources, we’re changing that narrative entirely.

The Hidden Cost Crisis in Machine Control

Traditional machine control solutions often come with a web of hidden expenses:

- Inflated purchase prices with limited negotiation power

- Expensive proprietary repairs that can’t be done in-house

- Installation delays costing thousands in downtime

- Technical support that leaves you waiting when time is money

- Parts monopolies that drive up maintenance costs

The result? Many operators pay 40-60% more than necessary whilst surrendering control of their own equipment.

Your Path to Machine Control Independence

Red Edge Resources offers a fundamentally different approach. We don’t just sell you equipment – we empower you to take complete control of your machine control ecosystem.

Stonex STX-Dig: Precision Without the Premium Price

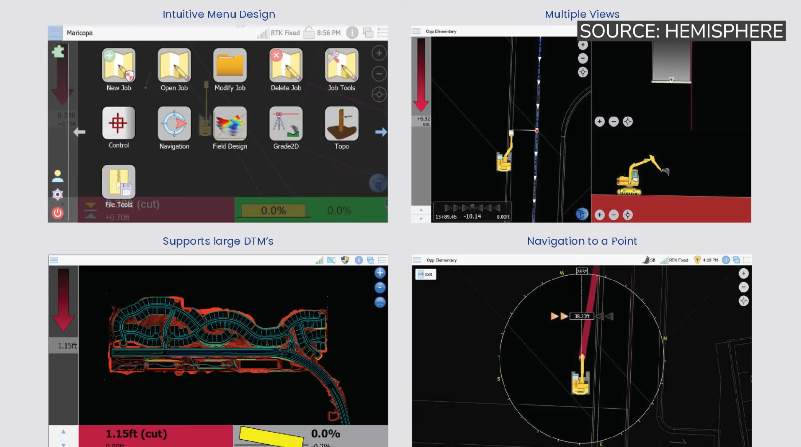

Our Stonex STX-Dig and Hemisphere systems deliver enterprise-grade accuracy at a fraction of traditional costs. With centimetre-level precision and intuitive interfaces, you get:

- 50% lower acquisition costs compared to major competitors

- Flexible financing solutions tailored to your cash flow

- No vendor lock-in – you own your technology completely

- 3-year comprehensive warranty for complete peace of mind

Flexible Installation Options: Your Choice, Your Control

At Red Edge Resources, we understand that every operation has different needs and capabilities. That’s why we offer complete flexibility in how your systems are deployed:

Option 1: Complete Red Edge Installation

- Professional installation by our certified technicians

- Fully-equipped mobile tech vehicles come to your site

- ‘Fixed off the Float’ – systems tested and calibrated before you start work

- On-site installation, un-installs, re-installs as needed

- Comprehensive system setup and calibration for optimal performance

Option 2: Calibration-Only Service

- You handle the installation using our detailed guides

- Red Edge performs precision calibration to ensure accuracy

- Professional verification of system performance

- Cost-effective option for experienced teams

- Same warranty coverage as full installation

Option 3: Complete DIY with Support

- Train your team through our certification programmes

- Full remote support throughout the process

- Step-by-step guidance via phone, email, or Teams

- Maximum cost savings whilst maintaining quality standards

Full Remote Support: We’re Always There When You Need Us

Every Red Edge system comes with comprehensive remote support capabilities:

- Remote access for troubleshooting and adjustments

- Real-time assistance during critical operations

- Software updates and system optimisation

- Priority support 6am to 6pm, Monday to Saturday

- 2-hour average response time for emergency calls

Game-Changing Training Programmes: Build Your Own Expertise

Here’s where Red Edge Resources truly differentiates itself. Instead of keeping you dependent on expensive technicians, we’re launching comprehensive certification programmes that put the power back in your hands:

New: Stonex STX-Dig Installation Masterclass

- Self-paced online learning that fits your schedule

- Complete installation certification for your team

- Downloadable resources for ongoing reference

- Real-world scenarios based on Australian job sites

Hemisphere VR1000 Installation Masterclass

- Comprehensive technician training covering every aspect

- Modular course structure from basics to advanced calibration

- Hands-on measurement and setup techniques

- Professional certification recognised across the industry

Complete Operator Training: From Management to Machine

Beyond installation expertise, Red Edge Resources provides comprehensive operator training that ensures everyone in your organisation speaks the same language when it comes to machine control.

Stonex STX-Dig Operator Guide

- Complete system operation from startup to shutdown

- User-friendly interface training for maximum productivity

- Troubleshooting guides for common operational issues

- Best practice techniques developed from real Australian job sites

- Management overview modules for supervisors and project managers

Hemisphere VR1000 Operator Guide

- GradeMetrix software mastery for advanced excavation work

- IronTwo display navigation and customisation

- Job management training including file formats and modifications

- Surface display optimisation for different project types

- Comprehensive troubleshooting and maintenance procedures

The Red Edge Training Ecosystem

When your entire team, management, workshop and operators understands the technology:

- Reduced downtime from operator errors

- Faster project completion through optimised workflows

- Lower support costs with in-house troubleshooting

- Improved safety outcomes through proper system use

- Better ROI on your machine control investment

One Training Platform, Complete Coverage: From the CEO understanding the business case to the operator maximising daily productivity, Red Edge Resources ensures everyone in your organisation can contribute to machine control success.

The Bottom Line: Train your team once, save thousands on every future installation.

Complete Cost Control Across Every Touchpoint

Purchase Power

- Direct distributor relationships eliminate middleman markups

- Volume pricing available for fleet installations

- Flexible payment terms including lease-to-own options

Installation Excellence

- Choose your preferred installation method – full service, calibration-only, or DIY

- Certified in-house teams reduce machine control costs by 45%

- 1-2 day installation timeframes minimise downtime

- Your trained technicians handle future installs independently

Repair Revolution

Warranty Protection That Actually Protects

- 3-year comprehensive warranty on all systems

- No hidden exclusions or fine print surprises

- Australian warranty law compliance with full consumer protection

- Local support means faster warranty service

Technical Support That Actually Supports

- Full remote support capabilities on all systems

- 2-hour average response time for emergency calls

- Email, phone, and text support on your preferred channel

- 100% customer retention rate speaks to our commitment

The Red Edge Advantage: Real Numbers, Real Savings

Case Study Snapshot: A typical Red Edge client with 3 excavators saves approximately:

- $45,000 on initial system purchase vs. major competitors

- $15,000 annually on installation and service costs

- $8,000 annually on parts and repairs

- $12,000 in reduced downtime through faster service

Total 3-year savings: $125,000+

Reclaim Control Today

The machine control industry has trained machine owners to accept high costs and limited control. We reject that model entirely.

At Red Edge Resources, you get: ✓ Premium technology at transparent, competitive prices ✓ Complete ownership of your machine control systems ✓ Flexible installation options to suit your operation ✓ Full remote support on every system ✓ 3-year warranty protection for complete peace of mind ✓ In-house expertise through our certification programmes ✓ Local support with genuine care for your success ✓ Proven results with 100% customer retention

Ready to take back control?

Contact us directly at 1300 769 359 or visit www.rededgeresources.com.au to discover how much you could save whilst gaining complete operational independence.

Don’t let another project pass with inflated machine control costs. Your competition isn’t waiting – and neither should you.

Red Edge Braided Cables: Engineered for Extreme Conditions in Machine Control Applications

Published: June 23, 2025 | By Red Edge Resources

Introduction: Why Cable Quality Matters in Machine Control

In the demanding world of machine control technology, every component must perform flawlessly under extreme conditions. Red Edge braided cables represent the critical link between sensors, displays, and control systems, ensuring reliable data transmission in the harshest environments that mining, earthmoving, and construction operations can present.

Cable failures are one of the most common causes of machine control system issues — and they’re almost always preventable with the right cable selection and installation techniques.

What Makes Red Edge Braided Cables Superior?

Engineered for Tough Conditions

Red Edge braided cables are specifically designed to excel in the harshest environments, built to withstand the rigorous demands of mining, earthmoving, and technology industries. Our cables represent your ultimate solution for durability and reliability in machine control applications.

Superior Construction Features

Red Edge braided cable advantages include:

- Continuous abrasion resistance – Resists wear and tear in rugged conditions

- Vibration tolerance – Maintains secure connections even in high-vibration environments

- UV exposure protection – Offers superior resistance to sunlight and harsh weather

- Chemical resistance – Stands up to solvents and chemicals without degrading

- Sudden movement durability – Ensures consistent performance under heavy strain

Built for Heavy Industries That Build the Future

Whether in mining sites, earthmoving operations, or cutting-edge technology applications, Red Edge braided cables deliver unmatched performance in the toughest conditions, protecting your investment in machine control technology.

Key Benefits of Red Edge Braided Cables

1. Reduced Downtime

Durable construction benefits provide:

- Fewer cable failures reducing unexpected system shutdowns

- Consistent performance throughout extended operational periods

- Reliable connections maintaining system integrity

- Reduced maintenance requirements minimizing service interruptions

- Enhanced operational continuity for critical projects

2. Enhanced Performance

Reliable connection advantages deliver:

- Consistent data transmission ensuring accurate machine control

- Stable signal integrity throughout cable movement cycles

- Optimal system performance with minimal signal degradation

- Smooth operations without connectivity interruptions

- Professional reliability meeting demanding application requirements

3. Cost Savings

Long-term value benefits include:

- Extended cable life reducing replacement frequency

- Lower maintenance costs through superior durability

- Reduced labor expenses from fewer cable-related service calls

- Investment protection through quality construction

- Operational efficiency minimizing downtime-related losses

Applications in Machine Control Systems

STX-DIG System Integration

Red Edge braided cables are essential for Stonex STX-DIG installations, providing:

- Reliable sensor connections for accurate positioning data

- Durable display connections ensuring clear operator feedback

- Robust power supply cables maintaining consistent system operation

- Flexible installation options adapting to various excavator configurations

- Professional-grade reliability meeting demanding field conditions

VR1000 System Applications

For Hemisphere VR1000 systems, our braided cables deliver:

- Secure IronTwo display connections ensuring reliable operator interface

- Durable sensor chain cables maintaining accurate positioning feedback

- Flexible routing options adapting to complex installation requirements

- Long-term reliability throughout extended operational periods

- Professional installation support through our comprehensive training programs

Professional Cable Installation Techniques

Cable Run Planning

Proper cable routing and management requires:

- Strategic route planning avoiding heat sources and pinch points

- Anchor point identification every 300-500mm for secure mounting

- Movement accommodation providing slack at articulating joints

- Protection planning for areas requiring additional cable guards

- Professional installation following industry best practices

Our VR1000 Installation Masterclass includes comprehensive cable management training covering these critical installation techniques.

Looming and Protection Techniques

Professional cable protection encompasses:

- Spiral wrap applications for cable bundles and flex zones

- Split loom installation for general cable protection

- Braided sleeving providing maximum flexibility and abrasion resistance

- Strategic tie placement every 200-300mm along straight runs

- Heat source avoidance protecting cables from engine and hydraulic heat

Avoiding Common Installation Mistakes

Professional installation practices prevent:

- Pinch point damage through careful routing around articulating joints

- Heat damage by avoiding engine exhaust and hydraulic systems

- Abrasion wear through proper cable protection and securing

- Connection failures via secure mounting and strain relief

- Premature wear through professional installation techniques

Sensor Chain Cable Specifications

Standard M12 Connections

Red Edge sensor chain cables feature:

- Standard 5-pin M12 connectors (male to female)

- Flexible length options accommodating various installation requirements

- Daisy-chain capability allowing multiple cable connections for extended runs

- Professional-grade construction ensuring reliable sensor communication

- Easy installation with secure M12 connection system

Installation Flexibility

Sensor chain advantages include:

- Modular cable lengths providing installation flexibility

- Secure connection system ensuring reliable sensor communication

- Extension capabilities through multiple cable connections

- Professional reliability meeting demanding field conditions

- Easy maintenance with accessible connection points

Integration with Red Edge Resources Training

Comprehensive Cable Management Training

Our professional training programs include:

- Cable routing best practices for optimal installation results

- Protection techniques ensuring long-term cable reliability

- Installation procedures following industry standards

- Troubleshooting methods for cable-related issues

- Professional certification for installation technicians

STX-DIG Installation Masterclass

The STX-DIG Installation Masterclass covers:

- Cable management techniques specific to Stonex systems

- Professional routing methods ensuring optimal performance

- Protection strategies for demanding excavation environments

- Installation best practices preventing common cable failures

- Quality assurance procedures ensuring professional results

VR1000 Installation Training

Our VR1000 Installation Masterclass includes:

- IronTwo display cable installation with professional mounting techniques

- Sensor chain cable management ensuring reliable positioning feedback

- Cable protection strategies for articulating excavator joints

- Professional installation procedures meeting manufacturer specifications

- Troubleshooting techniques for cable-related system issues

Quality Assurance and Testing

Rigorous Testing Standards

Red Edge braided cables undergo:

- Abrasion resistance testing ensuring durability in harsh conditions

- Vibration testing verifying performance in high-movement environments

- UV exposure testing confirming long-term weather resistance

- Chemical resistance testing ensuring compatibility with industrial environments

- Flexibility testing verifying performance through repeated movement cycles

Professional Installation Support

Quality assurance includes:

- Professional installation guidance through comprehensive training

- Technical support for complex installation challenges

- Quality verification procedures ensuring optimal performance

- Ongoing support throughout the cable lifecycle

- Professional certification for installation technicians

Technical Support and Service

Comprehensive Support Services

Red Edge Resources provides complete support including:

- Technical assistance for cable selection and installation

- Professional installation services ensuring optimal performance

- Troubleshooting support for cable-related issues

- Replacement services with genuine Red Edge cables

- Training programs for professional installation techniques

Contact us at 1300 769 359 for complete cable support services.

Professional Repair Services

Our technical repair facility offers:

- Cable inspection services identifying potential issues before failure

- Professional repair services for damaged cable assemblies

- Replacement cable supply with genuine Red Edge products

- Installation support ensuring proper cable routing and protection

- Preventive maintenance extending cable service life

Investment Protection and Value

Long-Term Value Proposition

Red Edge braided cables provide:

- Superior durability extending operational life significantly

- Reduced maintenance costs through reliable performance

- Enhanced system reliability minimizing unexpected failures

- Professional quality supporting your reputation for excellence

- Investment protection through quality construction and support

Return on Investment

Cable investment benefits include:

- Reduced downtime costs through reliable performance

- Lower maintenance expenses via superior durability

- Enhanced productivity through consistent system operation

- Professional differentiation through quality installations

- Long-term savings through extended cable life

Getting Started with Red Edge Braided Cables

Professional Consultation

Our experienced team provides:

- Cable selection guidance based on your specific applications

- Installation planning for optimal cable routing and protection

- Training recommendations ensuring professional installation

- Technical support throughout the installation process

- Quality assurance through professional installation services

Contact Information

Ready to upgrade your machine control installations with superior cable quality?

Phone: 1300 769 359Website: www.rededgeresources.com.auTraining: Professional Installation TrainingServices: Complete Support Solutions

Visit our Knowledge Portal for technical resources and installation guides.

Conclusion

Red Edge braided cables represent the foundation of reliable machine control systems, engineered specifically for the demanding conditions of mining, earthmoving, and construction operations. The combination of superior construction, professional installation support, and comprehensive training ensures that your machine control investments deliver maximum value and long-term reliability.

From the rigorous testing standards to the professional installation techniques taught in our comprehensive training programs, Red Edge braided cables provide the durability, reliability, and performance necessary for professional success in demanding applications.

Ready to protect your machine control investment with superior cable quality? Contact Red Edge Resources today to discover how our braided cables can enhance the reliability and performance of your machine control systems.

Red Edge Resources is Australia’s leading provider of machine control solutions and professional-grade cables, offering comprehensive installation training and support services. With extensive experience in demanding applications, we’re your trusted partner for reliable machine control technology.

The world of machine control technology offers several excellent options for excavator guidance systems, with Stonex STX-DIG and Hemisphere VR1000 representing two of the most advanced solutions available today.

Benefits of Stonex Machine Control: Transforming Excavation Operations with Advanced Technology

Published: June 23, 2025 | By Red Edge Resources

Introduction: Why Stonex Machine Control Delivers Superior Results

Stonex machine control systems represent the cutting edge of excavation technology, delivering measurable improvements in productivity, accuracy, and operational efficiency. With solutions ranging from basic 1D systems to advanced 3D guidance, Stonex provides scalable technology that adapts to your specific operational requirements while delivering consistent, professional results.

At Red Edge Resources, we’ve witnessed firsthand how Stonex machine control transforms excavation operations across Australia, helping contractors achieve superior results while reducing costs and improving safety.

Key Benefits of Stonex Machine Control Systems

1. Enhanced Productivity and Efficiency

Faster Excavation Operations

Stonex machine control productivity benefits include:

- 20-35% reduction in excavation time through optimized digging patterns

- Faster project completion with consistent, accurate work

- Reduced cycle times through precise bucket positioning

- Elimination of manual grade checking saving time and labor costs

- Continuous operation without frequent surveyor intervention

Streamlined Workflows

The STX-DIG Android software interface provides:

- Real-time communication between system components

- Intuitive operation reducing operator learning curves

- Seamless data integration with project plans and specifications

- Automated calculations for cut/fill operations

- Instant feedback on excavation progress

2. Exceptional Accuracy and Precision

Millimeter-Level Positioning

Stonex accuracy advantages deliver:

- Precise bucket position monitoring with real-time feedback

- Consistent grade control regardless of operator experience

- Accurate depth management for utility and foundation work

- Precise slope matching for drainage and road construction

- Quality assurance through continuous position monitoring

Scalable Precision Solutions

Stonex systems adapt to different accuracy requirements:

- 1D systems: Vertical leveling with rotating laser compatibility

- 2D systems: Grade and cross-slope control for enhanced precision

- 3D systems: Complete bucket control for complex excavation work

Learn more about our Stonex machine control solutions and how they can transform your operations.

3. Cost Reduction and ROI Benefits

Material Savings

Stonex cost benefits include:

- Reduced over-excavation through precise bucket control

- Minimized material waste with accurate positioning

- Optimized fuel consumption through efficient operation patterns

- Lower equipment maintenance costs via reduced wear and tear

- Decreased rework requirements through first-time accuracy

Labor Efficiency

Operational savings encompass:

- Reduced crew requirements with single-operator capability

- Eliminated grade checking personnel through automated systems

- Faster training periods with intuitive interfaces

- Consistent performance regardless of operator skill level

- Enhanced crew productivity through reliable technology

4. Easy Installation and Implementation

Quick Setup Process

Stonex installation benefits provide:

- 1-2 day installation timeframes minimizing equipment downtime

- Easy-to-install hardware designed for field conditions

- Minimal machine modifications preserving equipment integrity

- Flexible mounting options adapting to various excavator types

- Professional installation support ensuring optimal performance

Our STX-DIG Installation Masterclass ensures technicians can independently install and calibrate systems for maximum efficiency.

Scalable Implementation

System flexibility allows:

- Start with 1D systems and upgrade as requirements grow

- Adaptable configurations for different machine types

- Modular design enabling future enhancements

- Compatibility with various reference systems

- Investment protection through upgradeable technology

5. User-Friendly Interface and Operation

Android-Based Software

The STX-DIG Android interface offers:

- Familiar touchscreen operation similar to smartphones and tablets

- Intuitive menu navigation reducing training requirements

- Real-time visual feedback with clear graphical displays

- Customizable settings adapting to operator preferences

- Easy data management with cloud connectivity options

Operator Benefits

User experience advantages include:

- Reduced operator fatigue through automated guidance

- Enhanced confidence with clear visual indicators

- Improved job satisfaction through consistent results

- Faster skill development with intuitive technology

- Better situational awareness through comprehensive displays

6. Safety Improvements

Enhanced Operational Safety

Stonex safety benefits provide:

- Reduced ground personnel requirements minimizing exposure risks

- Improved visibility through clear display information

- Consistent operations reducing human error potential

- Better hazard awareness with real-time positioning data

- Automated safety checks through system monitoring

Risk Mitigation

Safety enhancements include:

- Precise utility location reducing strike risks

- Accurate slope control preventing over-excavation hazards

- Consistent performance eliminating guesswork

- Real-time alerts for operational parameters

- Professional installation ensuring system reliability

Specific Applications and Benefits

Utility Installation and Trenching

Stonex excels in utility work through:

- Precise depth control for safe utility installation

- Accurate line and grade following utility plans exactly

- Reduced utility strikes through precise positioning

- Consistent trench profiles meeting specification requirements

- Faster installation times with automated guidance

Site Preparation and Earthmoving

Site preparation benefits include:

- Accurate cut and fill operations optimizing material movement

- Precise grade establishment for building foundations

- Consistent surface preparation meeting engineering specifications

- Reduced surveying requirements through automated control

- Enhanced project quality with millimeter-level accuracy

Road Construction and Infrastructure

Infrastructure project advantages encompass:

- Precise slope matching for drainage and road construction

- Accurate subgrade preparation for pavement installation

- Consistent cross-sections meeting design specifications

- Reduced material usage through precise excavation

- Faster project completion with automated guidance

Training and Support Benefits

Comprehensive Training Programs

Red Edge Resources provides extensive training programs including:

- STX-DIG Installation Masterclass for technician certification

- Operator training courses for system users

- Best practices workshops for optimal performance

- Troubleshooting training for technical support

- Ongoing education for technology updates

Professional Support Services

Comprehensive support includes:

- Technical assistance for setup and operation questions

- Remote diagnostics for troubleshooting issues

- Regular maintenance programs ensuring continued performance

- Software updates with enhanced functionality

- Emergency support for critical operations

Contact us at 1300 769 359 for complete support services.

Integration with Red Edge Resources Services

Professional Installation

Our experienced team provides:

- Expert system design based on your specific requirements

- Professional installation ensuring optimal performance

- Comprehensive testing verifying system accuracy

- Operator training for successful implementation

- Ongoing support throughout the system lifecycle

Technical Repair Services

Our technical repair facility offers:

- Professional repair services for Stonex equipment

- Genuine parts supply ensuring optimal performance

- Fast turnaround times minimizing equipment downtime

- Quality assurance through certified procedures

- Preventive maintenance extending system life

Return on Investment Analysis

Measurable Benefits

Stonex ROI typically demonstrates:

- Payback periods of 6-12 months depending on usage intensity

- 20-35% productivity improvements in excavation operations

- 15-25% reduction in fuel consumption through optimized operation

- Significant quality improvements reducing rework costs

- Enhanced competitive positioning enabling premium pricing

Long-Term Value

Investment protection includes:

- Scalable technology growing with your business

- Regular updates maintaining cutting-edge capabilities

- Strong resale value protecting your investment

- Comprehensive support ensuring optimal performance

- Technology leadership positioning for future opportunities

Future Technology and Innovation

Continuous Development

Stonex innovation focus encompasses:

- Enhanced software features with regular updates

- Improved hardware reliability through ongoing development

- Advanced connectivity options for modern workflows

- Integration capabilities with emerging technologies

- User feedback incorporation for practical improvements

Technology Leadership

Staying current with Stonex technology provides:

- Access to latest features as they become available

- Competitive advantages through advanced capabilities

- Future-proof investments with upgrade pathways

- Industry leadership positioning in your market

- Ongoing support from technology experts

Getting Started with Stonex Machine Control

Professional Consultation

Our team provides:

- System selection guidance based on your specific needs

- Site assessment for optimal installation planning

- Training recommendations ensuring successful implementation

- Support planning for long-term success

- Investment analysis demonstrating ROI potential

Contact Information

Ready to experience the benefits of Stonex machine control?

Phone: 1300 769 359Website: www.rededgeresources.com.auTraining: Professional Training ProgramsServices: Complete Support Solutions

Visit our Knowledge Portal for technical resources and system documentation.

Conclusion

Stonex machine control systems deliver comprehensive benefits that transform excavation operations through enhanced productivity, exceptional accuracy, cost reduction, and improved safety. The combination of user-friendly technology, professional installation, and comprehensive support ensures that your investment delivers maximum value and long-term success.

From the intuitive Android-based interface to the scalable system configurations, Stonex technology adapts to your specific operational requirements while providing the reliability and performance necessary for professional success. The measurable benefits in productivity, accuracy, and cost reduction make Stonex machine control an essential investment for forward-thinking contractors.

Ready to transform your excavation operations? Contact Red Edge Resources today to discover how Stonex machine control can deliver superior results for your business.

Red Edge Resources is Australia’s leading provider of Stonex machine control solutions, offering comprehensive installation, training, and support services. With extensive experience and professional certification programs, we’re your trusted partner for advanced excavation technology.